What Is Hardware-In-Loop (HIL) and Software-In-Loop (SIL) Testing? A Complete Guide

|

|

You know, how young parents hesitate to introduce new foods to their kids, as they are unsure of how they will react? Understanding how complex systems behave before they are implemented in the real world is equivalent to that in the engineering world. Verifying system behavior without risking actual equipment, safety, or costly prototypes is necessary. This is regardless of whether it is the braking logic in an electric car, the sensor feedback loops of a robot, or the flight control algorithms of an aircraft. Hardware-In-Loop (HIL) and Software-In-Loop (SIL) testing are essential validation techniques in embedded systems and control engineering.

But as technology updates, these methods are not working with continuous delivery, cloud pipelines, high-level software automation, and AI-driven test systems. Let us take a stroll into the concepts of SIL and HIL. This blog covers both basic principles and innovative applications. Also, it explains how AI-powered tools complement these techniques with an end-to-end testing method.

| Key Takeaways: |

|---|

|

Before that, a small detour to understand:

What is “In-Loop” Testing?

It is better for the readers to understand what “in-loop” means before diving into more complicated definitions. Historically, testing was done after hardware prototypes were built. But prototypes are expensive and take time to be built. Also, they are challenging to test in rare or risk scenarios. In-loop techniques solved these hurdles by putting together hardware, software, or the entire system in a regulated simulation loop.

This means:

- You can simulate feedback from the real world.

- You are able to mimic failure situations.

- A physical prototype is not mandatory for early-stage testing.

- You can rapidly conduct thousands of automated iterations.

Also (…happily), you are safe to break things.

What is Software-In-Loop (SIL)?

At the core, Software-In-Loop testing is a simulation-driven methodology in which the environment, plant, and sensors are all replicated in simulation, and only software is verified.

In this stage, there is no physical hardware.

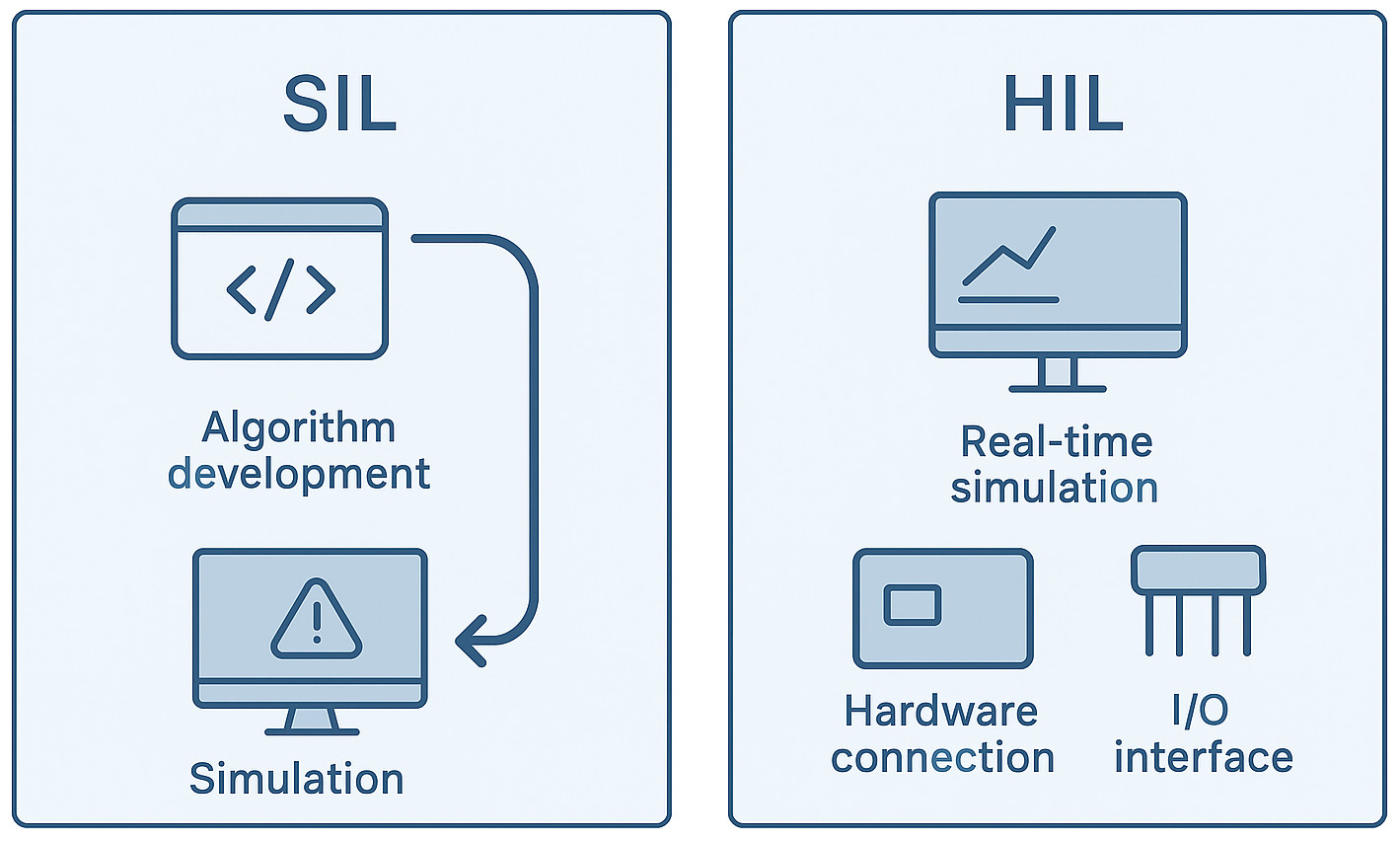

SIL testing is well-suited for algorithm development, logical accuracy, software module integration, regression testing, validating control strategies, and model-based design workflows. It is placed in the early to middle phase of the validation funnel.

SIL offers the following benefits because it doesn’t need hardware:

- Low cost

- High speed

- High scalability

- Early defect detection

- Easy automation

In a common SIL setup, the simulated plan model is combined with control logic that engineers write (usually in C/C++, MATLAB/Simulink-generated code, or embedded languages). The plant model represents system dynamics, including mechanical, thermal, pneumatic, electrical, hydraulic, and multi-domain behaviors.

SIL is ideal for batch testing large parameter sweeps, as this simulation can function on a desktop or server faster than real time.

What is Hardware-In-Loop (HIL)?

In comparison to SIL, Hardware-In-Loop testing utilizes actual hardware.

- An ECU

- A motor controller

- A flight computer

- A robotic arm controller

- A microcontroller board

- A DSP

- Personalized FPGA design

The above are some instances of the hardware.

The sensors, actuators, environment, loads, and failures are still simulated. But timing restrictions, electrical interfaces, and signal-level fidelity are suddenly bought when real hardware is present.

HIL Brings the Physical World Into the Process

Examples are:

- Feeding fake sensor data to test braking ECUs.

- Simulating motor loads for an EV inverter.

- Emulating wind scenarios for drone autopilots.

- Simulating robot joint torques for manipulator arms.

HIL places the hardware under test (HUT) inside a real-time simulation loop.

Real time refers to:

- No delays

- Deterministic implementation

- Precise timing (microseconds to milliseconds)

The full test fails if the simulation delays because embedded hardware depends on steady, consistent timing.

A Brief Historical Perspective

The start of in-loop testing goes back to the aerospace and defense sectors in the ’60s and ’70s. Flight control software was verified utilizing early HIL systems without risking pilots or aircraft. Automotive came next, first with engine ECUs, then with ABS, and finally with modern ADAS safety systems. Power electronics embraced it for grid simulation and inverter design, while robotics uses it for motion control.

HIL is now widely utilized:

- Automotive OEMs and Tier 1 suppliers

- Aerospace manufacturers

- Robotics companies

- Renewable energy and power grid research

- Medical device testing

- Spacecraft and satellite systems

This random historical addition illustrates how deeply embedded these methods are in industries where safety is important.

How are SIL and HIL Different?

While Software-In-Loop and Hardware-In-Loop testing have similar objectives, they both validate system behavior under simulated conditions. The two methods work in fundamentally different domains and expose very different classes of problems. The majority of SIL is detected in the abstract world. In a completely software environment, concepts, control logic, and algorithms are verified at this stage. Since there is no real hardware involved, the system behaves as per the mathematical models and perfect conditions. SIL is fast, adaptable, and economical. It is good for early development cycles where engineers are examining ideas, enhancing algorithms, or validating logic flow. The job is to ensure that the software “thinks correctly” without being limited by practical restrictions.

In comparison, HIL moves the spotlight from theoretical accuracy to real-world application. Here, the goal is to understand how real hardware responds to the continuous flow of simulated sensor and environment data. This is rather than only validating how the software behaves in simulation. Once hardware comes into the loop, the system becomes sensitive to issues that never emerge in SIL. System performance can be highly impacted by:

- Hardware-introduced timing subtleties

- Communication lags

- Electrical tolerances

- Processor load variations

- Interrupt behavior

A chunk of logic that seems good in simulation can mess up once it hits actual hardware. Timing variations, ADC sampling jitter, CAN bus latency, shaky sensor signals, or messy power noise can throw it off. Due to this, engineers use HIL testing. It helps catch hidden glitches early. It helps in tweaking circuits and firmware without requiring a complete product.

This is in contrast to how fast each method progresses things. SIL helps teams move fast. It tests multiple scenarios, validating rare issues, while adjusting code almost immediately. There are no delays in setting up. On the flip side, HIL takes extra steps. Devices need hooking up, fine-tuning, and the right settings, plus the system gets to keep the right timing. As a result, HIL runs fewer tests, yet they are more in-depth. Saved for instances when the precise timing, gear matching, or safe responses really matter. While SIL casts a massive net, HIL drills down with tight focus.

Another important difference? The type of issues each test detects. Instead of catching logic defects, like wrong code, shaku controller performance when settings change, or sudden fights between software parts. The SIL handles all of these issues. On the other hand, HIL catches stuff related to real-world setup:

- How do devices react to fast signal shifts?

- How do embedded codes talk with data channels?

- Processor behavior during glitches.

- Actual timing pressure shapes responses.

Often, it is only during HIL testing that teams pounce on sneaky lags or sequence hiccups that are neglected in clean, simulated SIL runs.

In short, SIL and HIL don’t fight each other. They work together. While SIL validates that the system’s logic is sound, steady, and tough on paper, HIL tests whether the actual hardware runs smoothly and dependably in real conditions.

They work together, detecting issues early, such as design errors or timing crashes. This is well before anything risky happens to actual devices, machines, people, or robots.

Modeling Foundations: Why Plant Models Matter So Much

Many guides skip this part, but the key to getting HIL or SIL is called plant modeling. Plant models simulate:

- Mechanics

- Dynamics

- Electromagnetics

- Control loops

- Thermodynamics

- Non-linearities

- Sensor noise

- Disturbances

- Failures

These models are written in:

- Simulink

- Modelica

- C/C++

- Python (for early prototyping)

- Proprietary modeling languages

The fidelity of these models defines the fidelity of SIL and HIL. A poor model generates wrong results, even if your HIL test bench is costly.

Industry Examples: HIL SIL in the Automotive World

The automotive sector may be the biggest consumer of existing SIL and HIL systems.

In electric vehicles:

- Battery management systems (BMS)

- Inverters

- Motor control units

- Onboard chargers

- Power distribution modules

In ADAS and autonomy:

- Lane-keep assist

- Adaptive cruise control

- Object detection

- Sensor fusion

- Drive-by-wire systems

HIL enables simulating:

- Sudden brake failures

- Sensor occlusions

- Slippery roads

- Tire blowouts

- Edge-case traffic scenarios

These would be too risky or infeasible to reproduce physically.

SIL in Robotics: From Arm Manipulators to Mobile Platforms

Robotics is unique as feedback loops are fast, highly non-linear, and often safety-critical.

SIL tests are used to verify:

- Trajectory planners

- Inverse kinematics solvers

- SLAM algorithms

- Safety boundaries

- Localization logic

Before sending a 6-DOF robot arm moving at high speed, you absolutely definitely 100% want to test it in simulation.

Real-Time Solvers Used in HIL

To satisfy microsecond-level constraints, HIL simulators use specialized solvers:

- Fixed-step ODE solvers

- Real-time discretized models

- FPGA-based physics acceleration

- Solver partitioning and scheduling

FPGA-based real-time simulation is extremely popular in power electronics because switching happens at tens of kHz.

Pitfalls and Challenges in HIL/SIL

Not everything is picture perfect.

Challenges:

- Maintaining accurate models

- Ensuring real-time constraints

- Hardware availability

- Complex setup and calibration

- Data synchronization

- Electrical safety (for high-voltage systems)

Even SIL, though easier, suffers from:

- Extreme reliance on oversimplified models

- Difficulty modeling physical noise or hardware quirks

- High computational load for large simulations

These challenges build a natural push toward automation and AI-assisted workflows.

Testing Standards Related to HIL and SIL

Safety-critical industries slap strict standards, for example:

Automotive

- ISO 26262

- ASPICE

Aerospace

- DO-178C

- DO-254

- ARP4754A

Industrial Safety

- IEC 61508

HIL/SIL are mandatorily recommended or required for compliance.

Digital Twins and the Future of SIL/HIL

Digital twins are high-fidelity virtual counterparts of physical systems. They are gaining importance in HIL/SIL workflows.

They aid:

- Consistent simulation of field behavior

- Predictive maintenance

- Closed-loop optimization

- Long-term stress testing

Digital twins blur the line between SIL, HIL, and full system emulation.

Read: Digital Twins in Software Testing Explained

CI/CD Integration: SIL and HIL in DevOps Pipelines

Modern engineering teams are increasingly integrating SIL and HIL into automated pipelines.

For example:

- SIL simulations run automatically on each commit

- HIL benches trigger nightly tests

- Results feed into dashboards and trend analytics

However, these systems test only embedded logic, not full end-to-end user workflows.

How AI-Powered Testing Tools like testRigor Complement HIL and SIL

SIL and HIL validate embedded systems but leave software layers untested:

- Cloud services

- Web apps

- Mobile apps

- APIs

- Device dashboards

- Data integrations

This is where testRigor becomes essential.

Why testRigor Fits Perfectly in a HIL/SIL Ecosystem

Natural Language Test Automation: Testers skip scripting, just list actions using everyday words. “Log in as admin, open the device dashboard, and verify that the battery level from HIL output is displayed correctly.”

This makes it simpler for different teams to work together. Here’s a guide showing how easily anyone can automate tests in plain English using testRigor – All-Inclusive Guide to Test Case Creation in testRigor

Validating End-to-End Behavior: HIL results usually go straight to bigger systems. testRigor validates:

- UI updates

- System alerts

- API data consistency

- Error handling

- Cloud synchronization

High Stability and Zero Flakiness: Old-school UI testing breaks easily. testRigor utilizes smart locators that barely require maintenance.

Full CI/CD Support: You can pair:

- SIL test results

- HIL test logs

- testRigor produced UI/API test reports

… all into a unified pipeline.

Regression Testing at Scale: While embedded teams adjust code, software teams test connections or processes at the same time.

Perfect Fit for Complex Systems: Industries using HIL/SIL often have:

- Extremely complex UIs

- Multiple test environments

- Regular integration points

- Strict reliability requirements

testRigor offers predictable, scalable automation for these upper layers.

Bringing it All Together

HIL and SIL tests are not just for special fields anymore. Instead, they have become key in current system development. They are particularly good when it comes to safety, speed, or consistency.

Yet these systems are not just sitting alone.

Products today combine:

- Embedded control systems

- Cloud services

- Web and mobile applications

- IoT data platforms

- End-user interfaces

To get a real working product, check every level. Start from the bottom, move up without skipping steps, as one weak spot breaks everything else.

That is why combining:

- HIL (hardware behavior)

- SIL (Software logic)

- testRigor (end-to-end testing)

… builds a full-on testing plan you can actually use right now.

Additional Resources

| Achieve More Than 90% Test Automation | |

| Step by Step Walkthroughs and Help | |

| 14 Day Free Trial, Cancel Anytime |