Digital Transformation in Engineering

|

|

The global engineering landscape is undergoing a seismic shift. Rapid technological innovations and an ever-increasing demand for quality, advancements, and speed drive this shift. Because of this, the digital transformation redefines how engineers design, develop, and deliver products and services.

Digital transformation has completely changed the working world. With the advent of cloud computing software, the Internet of Things (IoT), and automation, businesses can now communicate and deliver faster and serve a wider audience.

| Key Takeaways: |

|---|

|

This article will cover the following:

|

This article explores the concept of digital transformation in engineering, focusing on how organizations can use this revolution to gain a competitive edge.

What is Digital Transformation in Engineering?

Digital Transformation: Integration of digital technologies and tools into engineering processes, tools, and culture to improve quality, productivity, performance, innovation, and collaboration.

It is a strategic adoption that will fundamentally change how engineering work is done, from designing and manufacturing to project management and operations. Unlike traditional digitization (converting analog to digital) or digitalization (using digital tools to improve tasks), digital transformation redefines workflows, business models, and customer engagement.

Engineers, for example, can speed up innovation by using cutting-edge technologies like computer-aided design (CAD), simulation software, and advanced analytics.

Digital transformation also makes the industry safer for everyone. For example, in the manufacturing sector, equipment failures can be anticipated in advance using predictive maintenance systems that use machine learning (ML) algorithms, minimizing downtime.

Using digital platforms at every project lifecycle stage, engineers can streamline processes and drive innovation. This technology also contributes to a culture of collaboration, empowering teams to work together from any location.

Key Aspects of Digital Transformation in Engineering

Some of the key aspects of digital transformation are as follows:

- Adoption of Digital Tools: Using tools like CAD, simulation software, advanced analytics, and other technologies to enhance analysis, design, and testing processes.

- Digital Thread: All system data should have a single, authoritative source of truth, facilitating seamless collaboration and data exchange across engineering disciplines.

- Integration of Digital Technologies: Apply artificial intelligence (AI), ML, IoT, and cloud computing to improve and optimize manufacturing operations and enable new business models.

- Focus on Data-driven Decision Making: Use data analytics to gain insights, identify improvement areas, and make more informed decisions.

- Emphasis on Collaboration and Communication: Use digital platforms and tools to enhance collaboration and communication among engineering teams, clients, and other stakeholders.

Key Drivers of Digital Transformation in Engineering

Certain elements drive the digital transformation in engineering, from market pressure and customer expectations to globalization and sustainability requirements. Here are a few of the key drivers listed:

- Customer Expectations and Market Pressure: Customers expect faster innovation, customized solutions, and improved quality in products and services. Engineering firms are expected to deliver complex projects in a short time with fewer resources. Digital tools and technologies enable quicker prototyping, reduce errors, and enhance agility.

- Globalization and Distributed Teams: Engineering teams are spread across continents, and for smooth integration and operation across the globe, digital platforms like cloud, CAD, real-time simulation environments, and digital project management tools are very useful. They facilitate seamless integration and collaboration, reduce miscommunication, and speed up development cycles.

- Big Data and Predictive Analytics: Data has become a crucial aspect of the engineering sector. From sensors on machines to customer usage feedback, engineering teams actively use predictive analytics to predict maintenance issues, optimize designs, and improve product performance.

- Emergence of AI and Automation: AI has revolutionized how engineers analyze data, anticipate results, and automate repetitive tasks. AI reduced human effort and errors while improving accuracy and efficiency.

- Regulatory Compliance and Sustainability Goals: Compliance can be tracked using digital solutions to ensure all regulatory requirements are followed. Digital solutions also enhance environmental performance through life-cycle assessments (LCA), carbon footprint tracking, and energy modeling that are crucial in a sustainability-conscious world.

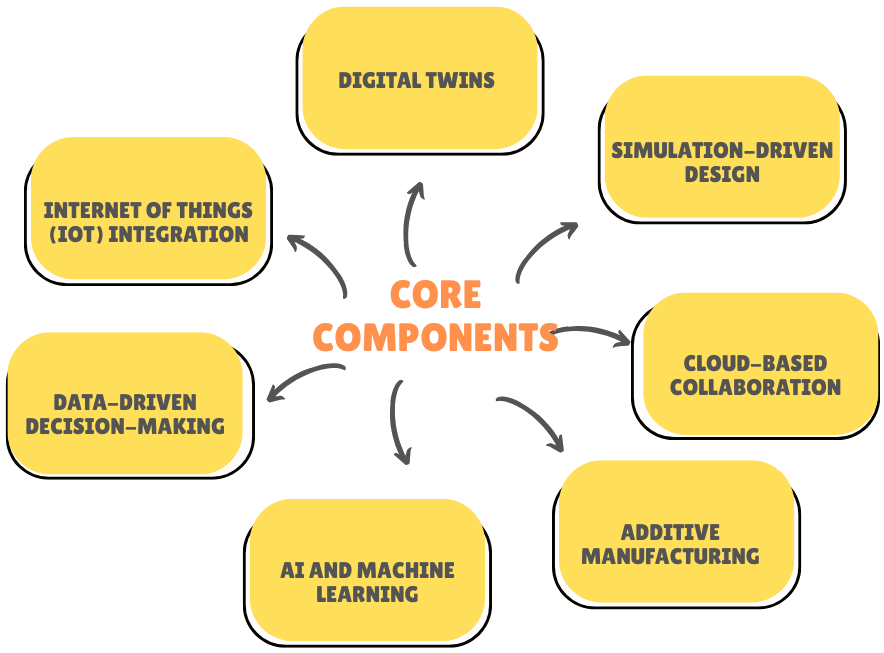

Core Components of Engineering Digital Transformation

Digital transformation and its core components enable engineers to make use of cutting-edge tools like CAD, simulation software, and advanced analytics for improved design, analysis, and project management.

Here are the core components of digital transformation in engineering:

1. Digital Twins

A digital twin is a virtual replica of a physical system, process, or asset. It can simulate real-world behaviour and is widely used in the aerospace (flight simulation), automotive, and construction industries. It enables real-time monitoring, product optimization, and predictive maintenance.

2. Simulation-Driven Design

Engineers can integrate simulation tools like Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) into design stages to test multiple iterations, minimizing physical prototyping.

3. Cloud-Based Collaboration

Diverse and geographically scattered teams can collaborate effectively using platforms like Autodesk Fusion 360, PTC Onshape, and Siemens Teamcenter that facilitate version control, concurrent design, and cross-functional collaboration.

4. Additive Manufacturing

Engineers can use 3D printing, which has evolved from rapid prototyping to producing functional parts, to design parts with complex geometries. This helps with enabling lightweighting, material savings, and just-in-time production.

5. AI and Machine Learning

AI can be used for design optimization, failure prediction, and material discovery. For example, there are various generative design tools that propose thousands of design alternatives based on predefined constraints and objectives.

6. Data-driven Decision-making

Using data analytics helps engineers to make informed decisions, optimize processes, and improve product development, fostering a data-driven culture. Data can also identify trends, predict potential issues, and enhance the overall performance of engineering projects.

7. Internet of Things (IoT) Integration

IoT consists of objects and devices equipped with sensors that gather and transmit data over the Internet. IoT applications can generate real-time data in supply chain logistics and self-driving cars, effectively bridging the gap between digital technology and physical reality. Read IoT Automation Testing Guide: Examples and Tools.

Benefits of Digital Transformation in Engineering

Digital transformation in engineering has several benefits, including:

- Increased Efficiency: Processes are streamlined and productivity maximized using automation and optimization tools. Using integrated project management platforms support coordination between team members and ensure projects are completed on schedule. This increased efficiency leads to better business outcomes.

- Faster Time to Market: Companies can accelerate development cycles by digitally transforming their engineering process. By using automation, simulation, and Agile workflows, time-consuming reworks are reduced, and products can be marketed faster. Read: The Impact of Test Automation on Time to Market.

- Improved Product Quality: Digital transformation helps engineering teams with real-time feedback, integrated quality checks, and predictive analytics using which more robust and reliable systems can be built.

- Enhanced Collaboration and Knowledge Sharing: Decision-making and collaboration can be improved as engineers, designers, suppliers, and customers can collaborate effectively on the same digital model. Additionally, using technologies like cloud computing, data is democratized, and teams can work efficiently across geographical locations.

- Cost Reduction: Product cost is significantly reduced by automating repetitive tasks, reducing physical or manual testing, and optimizing resource usage. Read: How to Save Budget on QA.

- Identifying Issues Faster: Using digital transformation tools and technologies helps engineers to proactively identify issues and make improvements. With IoT sensors and monitoring systems, equipment performance can be monitored in real-time.

- Increased Innovation Capacity: By using digital tools, most of the work is sped up and hence engineers can focus on creative problem solving and high-value design activities fostering continuous innovation.

Challenges and Barriers for Digital Transformation

Despite its benefits, digital transformation in engineering poses several hurdles:

- Legacy Systems and Infrastructure: Many organizations still use legacy systems that operate on outdated hardware and software. This limits the integration of modern digital tools and migration of data and systems becomes difficult. Read: How to test legacy systems?

- Skills Gap: Digital transformation requires a hybrid skillset, a combination of traditional engineering expertise and digital literacy skills. It needs engineers fluent in coding, data science, and AI which sometimes can be challenging.

- Cybersecurity Risks: Increased connectivity brings increased vulnerability with it. Protecting property, design files, and sensitive data from security threats and risks is a top concern. Read: Cybersecurity Testing in 2025: Impact of AI.

- Cultural Resistance: Fear of obsolescence and unfamiliarity with new technologies may lead to resistance from employees. Organizations should have effective change management in place in addition to upskilling programs for a smooth transition.

- High Initial Costs: The upfront cost of new platforms, training, and integrations can be costly, especially for smaller organizations and startups, although digital transformation brings long-term benefits.

Examples of Digital Transformation in Engineering

This section provides an overview of examples of digital transformation in engineering.

-

Computer-aided Design (CAD): Engineers use CAD software to conceptualize and refine designs with precision and speed. CAD drives modern engineering with its tools ranging from simple 2D drafting tools to sophisticated 3D modeling software.Autodesk is a popular CAD tool that most companies use to design.

-

Computer-aided Engineering (CAE): CAE tools can be used to simulate and analyze the engineering design performance under various conditions. Using CAE, engineers can identify potential problems and speed up the development cycle.AWS provides CAE solutions to create production-ready environments for design, simulation, and analysis workloads.

-

Predictive Maintenance: This is a data-driven approach to predict maintenance demands and proactively address issues. Engineering teams can gain valuable insights into potential failures before they occur using predictive maintenance.ServiceMax is a tool that helps organizations that can perform predictive maintenance and extend the asset lifespan and grow satisfaction.

-

Building Information Modeling (BIM) Software: Collaborators can use virtual modeling software, BIM, to collectively visualize, test, or simulate design-build concepts in detail.SketchUp is a BIM tool that offers 2D plans, 3D walkthroughs, mixed reality viewing, etc.

-

Mechanical Design Automation (MDA) Software: MDA software is used to automate repetitive design tasks and calculations. This way, engineers can focus on more creative problem solving. MDA also helps with the generation of complex mechanical designs and documentation.MDA tool, Solid Edge uses synchronous technology to accelerate product design, make fast revisions, and improve design data reuse among others.

-

Integrated Electronic CAD (ECAD) Software: ECAD tools provide capabilities for designing complex electronic systems. It also supports collaboration and the integration of electronic components with mechanical design and simulation software.Ansys Sherlock provides fast and accurate life predictions for electronic hardware at the early-stage design of the board, component, and system levels.

-

3D modeling Software: Engineers can use 3D modeling software to create a detailed virtual representation of physical components and environments. Visualizing concepts and communicating ideas is easier with 3D modeling software.SOLIDWORKS is a tool that provides 3D design and product development solutions, helping engineers conceptualize, create, validate, communicate, manage, and transform ideas into product designs.

-

Cloud-based Data Management: Using cloud-based data management facilitates data storage and access. Engineering organizations can centralize data and provide remote access to critical data using cloud software.The Snowflake Data Cloud helps companies with a data modernization strategy with functionalities including cloud-built data warehousing, cloud data lake, collaboration, data science, data engineering, applications, and a data marketplace across one or multiple clouds.

-

VR building Simulations: Virtual reality (VR) simulations can help with architectural visualization and design validation. They can be used to visualize building design and identify flaws before construction begins. VR technology also improves decision making and reduces overall cost.Prospect from IrisVR is a VR simulation tool empowering engineering teams to make informed decisions with confidence.

-

AI-powered Generative Design: With the help of user-defined constraints and objectives, generative design provides optimized solutions with the help of AI algorithms. This presents engineers with a range of design alternatives.Autodesk Fusion is a powerful AI-based generative design tool that generates thousands of manufacturing-ready solutions. It also streamlines the design process, reduces costs, and improves performance and quality of the final product.

Digital Transformation Project Examples

Here are a few use cases of digital transformation in engineering:

- Automotive: Auto companies like BMW and Tesla use AI, predictive analytics, and digital twins to optimize vehicle performance, manufacturing, and maintenance. Production lines use virtual crash testing and digital assembly lines.

- Aerospace: Airbus and Boeing aircraft manufacturers implement end-to-end digital threads, from design to maintenance, using digital twins, cloud-based PLM, and augmented reality for training and assembly.

- Civil and Structural Engineering: Smart cities and infrastructure projects now use BIM to manage assets across their lifecycle. Digital platforms are used to track energy usage, material wear, etc.

- Oil & Gas: Digital transformation helps oil & gas companies in predictive maintenance, reservoir simulation, and remote operations. This improves both safety and efficiency in a traditionally risk-heavy industry.

Digital Transformation: Future Outlook

It is an indisputable fact that the future of engineering will be digital. With emerging technologies like edge AI, blockchain, quantum computing, and augmented reality, digital transformation is set to further transform the field:

- Quantum Computing, Materials science, and optimization problems could be revolutionized. Read: What is Quantum AI?

- AR and VR will become standard tools for remote inspections and design reviews.

- Blockchain will secure supply chains and design data in multi-party collaborations. Read: Blockchain Testing: How to do it?

- Edge computing will help remote or embedded devices with real-time analytics.

Strategies for Successful Digital Transformation

Engineering organizations must adopt a strategic approach for successful digital transformation:

- Establish a Clear Vision: Align digital transformation objectives with business outcomes.

- Invest in the Right Tools: Choose and invest in scalable, interoperable platforms that support collaboration and analytics.

- Upskill the Workforce: Provide training and development to fill the digital skills gap.

- Start Small, Scale Fast: Start with pilot projects to demonstrate value before enterprise-wide adoption. Read: Scalability Testing: Automating for Performance and Growth.

- Promote Cultural Change: Encourage a mindset of agility, innovation, and learning.

Conclusion

Using digital tools and technologies in the engineering sector is not a luxury anymore but a necessity. As engineering sectors become more complex and competitive, organizations that opt for digital transformation will surely lead the industry in innovation, customer satisfaction, and efficiency.

The digital transformation is already taking place at a steady pace in engineering industries. The only question now is how well and how fast organizations can adapt to digital solutions.

| Achieve More Than 90% Test Automation | |

| Step by Step Walkthroughs and Help | |

| 14 Day Free Trial, Cancel Anytime |